At All-American Hose, we’ve built our reputation on manufacturing industry-leading quality firehose in the United States. It all started in 1969, when Snap-tite formed its Hose Products Division and in 1977, entered into a joint venture with a West German company to manufacture lay-flat hose in Union City, Pennsylvania. Snap-tite is credited with introducing the concept of large diameter hose (LDH) and driving its widespread use throughout North America. Today, virtually every fire department in America uses LDH to move water efficiently.

In 1980, Snap-tite bought out its partner to form Snap-tite Hose, Inc. In 1990, the Company purchased Ponn Hose and in 1995, it acquired National Fire Hose. Snap-tite sold the hose division to All-American Holdings, LLC in June 2010. In April 2016, a group of private investors acquired the assets of All-American Hose, making it one of the largest fire hose manufacturers globally.

Today, All-American Hose remains true to our commitment to engineer and manufacture the industry’s best firehose. Every day our team, 150-strong, works at the Company’s two facilities in Pennsylvania to deliver on that quality promise.

We, the All-American Team, will strive to set World Class manufacturing standards and World Class standards for the utmost performance driven selling organization, that partners with our distributor network to deliver to our end-users IRREPLACABLE brands; performance and customer service through superior products; value pricing; and market execution that satisfies all fire service industry requirements while delivering investor financial expectations.

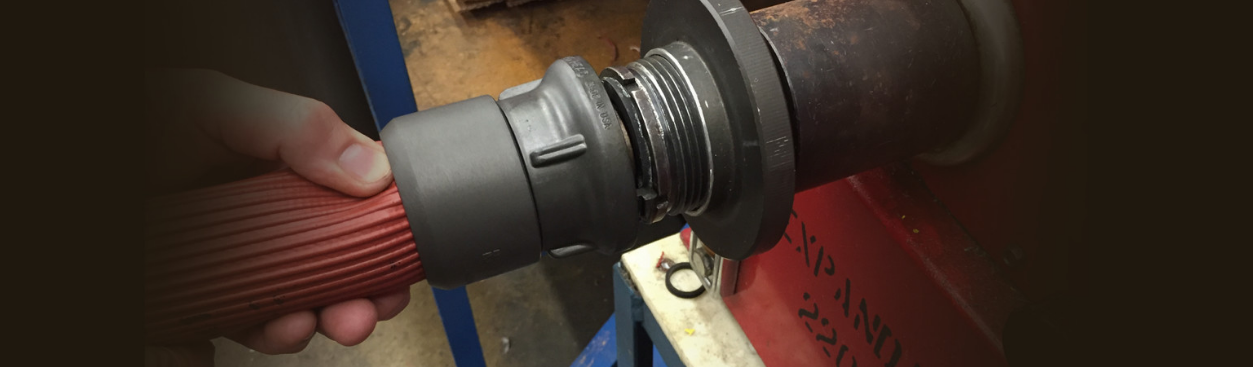

At All-American Hose, we ensure that the world’s best hoses also have the best coupling options. From extruded hard-coated aluminum to the ultra-light forestry connectors, we offer premium-quality couplings in the configurations you need to connect your hose with complete confidence.

Standard style coupling supplied with municipal and industrial hose. Twice as strong as brass and only one-third the weight. Hard-coated for extra wear resistance and helps prevent damage to swivel and threads. Three lugs on both male and female swivel. Expansion ring type.

The Liberator Way Out Coupling offers very durable directional indicators which are available in the NFPA colors. Aluminum rocker lug hard coated aluminum increases resistance to damage.

Lightweight cast aluminum, hard-coated to prevent corrosion and abrasion. Self-locking, 3-part clamp design ensures better coupling retention and reduces hang-up when laying hose in the field.

Suction hose couplings are extruded 6061-T6 lightweight, hard-coated, high-strength aluminum alloy. Long handles are finger-gripped and canted for clearance. Available in Female Long-Handle (NFL), Female Rocker-Lug (NFR), Male Rocker-Lug (NMR) and Male configurations. Expansion ring type.

Standard threaded forestry hose coupling that meets USFS Specification No. 5100-108. Only hard-coated extruded 6061-T6 lightweight, high-strength aluminum alloy couplings are used. Two-lug design. Expansion ring type.

Lightweight, high-strength aluminum quick-attach coupling for use with forestry hose. External lugs for fast action, no threads to damage and hard-coated for long service life. 1½" connecting face for both 1" and 1½" forestry hose. Expansion ring type.

Basic two-lug coupling that won’t snag and rolls easily while in use. Cast brass designed for heavy-duty industrial firehose applications where corrosion is a concern. Brushed brass finish. Expansion ring type.

深圳市柏赛智能科技有限公司

Copyright © 2016 Tank Parts Division All rights reserved.

技术支持:厦门博深网络技术有限公司 备案号:粤ICP备2020080590号-3