Application

The A6400 magnetic liquid-level gauge is especially designed for use in NH3 with chemical additives. Gauges are available for all tanks and any mounting position.

General Information & Features

These gauges are built to the highest standards of manufacturing and thoroughly field tested. The magnetic construction permits the complete sealing-off of the inside liquid from the outside gauge head and dial. This eliminates many hazards and permits dial replacement quickly without loss of liquid by simply removing two screws. All dial capsules are easy-to-read, hermetically sealed, vacuum tested and eliminate fogging. Dial pointers are silicone dampened. These gauges are UL listed for NH3 or LPG service.

Rochester‘s rugged gear drive is standard with shrouded stainless steel beveled gears especially designed to shed and work out any loose particles which might affect action. From the hermetically-sealed dial to the one-piece head, body and fusion welded float, each gauge is especially suitable for additive application and will provide long trouble-free service in even the most severe use. Mounting may be accomplished in all desired positions where circumstances permit.

Additional Information

Temperature

Standard range is -40°F to 176°F, -40°C to 80°C.

Accuracy

Accuracy depends upon proper gauge sizing and is typically ±5% of dial indication. Accurancy may be less due to variations in liquid temperature. Accuracy may be less for some tank shapes and sizes. Accuracy may be less near full and empty. Accuracy may be less if tank is not level. This gauge is not to be used for filling. All accuracy estimates are expressed as a percent of full scale.

Shock & Vibration

Suitable for mobile service applications.

Working Pressure

450 psig [31 Bar]

UL Listing

UL listed for NH3 service.

Counterbalance & Support Tube

Stainless Steel.

Gasket

Neoprene.

Mounting Screws

Stainless Steel.

All Other Components

Stainless steel, except for nickel plated alnico magnet.

Note: For installation instructions see MS-501/502 (mounting standards).

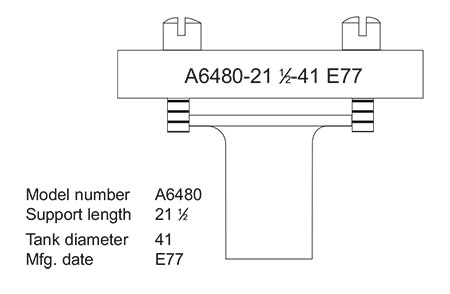

1. Gauge head size, Senior.

2. Tank diameter as shown on nameplate.

3. Mounting location (top, side, end, or angle).

4. If gauge is angle mounted, state degree of angle above or below the horizontal centerline.

5. If gauge is end mounted, state the shape of the tank head, hemispherical or semi-ellipsoidal.

6. The “H” dimension (distance in inches fro the surface of the tank to the gasket surface on the riser).

To order replacement gauge, simply furnish the information stamped on the hex wrenching flats as shown on example.

Note: Gauge head may also be stamped model and unique suffix number.

*Materials and specifications are subject to change without notice. Pressure ratings subject to change due to temperature and other environmental considerations.

Revised 06-19-2015

![]()

华滋智能是Rochester Gauges公司在亚太区的行业战略合作伙伴